WhatsApp)

WhatsApp)

PROCESS DESIGN OPTIMIZATION OF FUEL AND POWER CONSUMPTION IN CEMENT PLANT ... plant will benefit in the clinker .

PROCESS DESIGN OPTIMIZATION OF FUEL AND . PROCESS DESIGN OPTIMIZATION OF FUEL AND POWER CONSUMPTION IN CEMENT PLANT ... in the clinker grinding system because of ...

Simulation of clinker grinding circuits of cement plant ... of the power requirements of dry clinker ... based optimization of mineral grinding ...

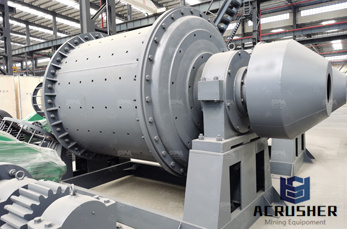

Traditional clinker grinding station adopts ball mill to grind clinker, and has much dust, loud noise and high energy consumption in the process of production, it ...

IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY ... Improved Cement Quality and Grinding Efficiency ... Grinding of clinker .

clinker grinding vrm. ... OPTIMIZATION OF PLANT ... FL receives cement plant order in Pakistan FL has been awarded an order from Power Cement ...

Optimization of continuous ball mills used for finishgrinding of cement ... for the prediction of the electrical power consumption in the clinker grinding ...

Burning alternative fuels can lead to instability in the clinker ... Mill optimization Grinding makes up a ... Expected benefits of a process optimization ...

Optimising raw material grinding. Our raw mill evaluation and optimisation program covers examination of the raw material grinding process from the mill feed to raw ...

Training Courses based on the Grinding Software ... Volume Load Power Kit ... 53. Energy Optimization Calculator

Excessive grinding should be avoided to save power ... Cement Mill Optimisation; Grinding of Clinker ... aid utilization and optimization of grinding aids in ...

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant. Sanjeev T. Patil. ... Appliion:Cement Plant, Clinker Grinding Unit, Thermal Power Plant.

Reducing the energy required in grinding clinker to cement: some ... Before optimization; ... Motor power (kW) 50.

optimization of clinker grinding power. Conventional Clinker Grinding A New Approach to the Prediction ... optimization, Modelling ABSTRACT The current ...

Clinker. At the outlet of the kiln, the clinker goes through a cooler, after which the clinker lumps must be broken before entering the final stage of grinding by ...

Clinker 60t Clinker (CaO compounds) 40t Co 2 + Dust 10kg ... Grinding Optimization ... • Reduced power consumption.

Optimization Of Verical Roller Mill For Raw Grinding In ... Power generation ... Supervision of process optimization, . Cement Raw Material,Clinker ...

Radiotracer Investigation of Clinker Grinding Mills for ... optimization of such mills will be possible if the ... considerable amount of power. Grinding of the clinker

cement grinding optimization. ... There is potential to optimise conventional cement clinker grinding ... Impact on Specific Power Consumption and ... grinding ...

Coal Crusher Clinker Grinding Unit; ... Pulverizer Ball Mill Optimization. ... Pulverizing System Optimization of Thermal Power Plant. ...

Multichamber cement mills,Clinker grinding ball mills ... Multichamber cement mills. For all dry grinding applications, cement production is certainly the most ...

Cement Grinding Optimization ... and around 40% of this energy is consumed for clinker grinding. ... "The tools of power: How to evaluate grinding mill ...

Hybrid simulation and energy market based optimization... 67 Wind Power Cement Plant Plant FRR Battery Fig. 2 Integration of wind power plant and battery

Objective of Ball mill optimization Mill performance ... grinding system Clinker Gypsum ... Damper position Separator fan power (kW) 49 . Grinding ...

WhatsApp)

WhatsApp)