WhatsApp)

WhatsApp)

Feb 14, 2016 Cement industries typically produce portland cement, although they also vertical grinding mill types for cement plants vertocal raw mill process.

Portland Cement Manufacturing Process Description17 ... In the wet process, water is added to the raw mill during the grinding of the raw materials in

Home >> Products >> raw milling process in cement plant . raw milling process in cement plant. Request for Quotation. ... cement raw mill, cement preheater, cement kiln,

Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silicate, new building ...

Cement Manufacturing Process. The raw materials needed to produce cement (calcium carbonate, silica, alumina, and iron ore) are generally extracted from limestone ...

A cement mill (or finish mill in North American usage) ... These have been used for many years for the less exacting rawmilling process, ...

PENTA Engineering Corp. completed a cement plant raw mill and kiln conversion project at Hagerstown for Lafarlcim.

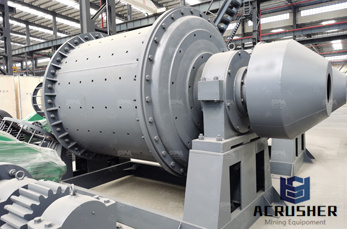

Preparation of cement raw materials. Raw Material Preparation. Home; About this site; About cement; List of plants ... Dry Process Ball Mills.

The ATOX Raw Mill is a highly efficient mill that grinds all types of raw materials ... Cement Process Sampling; ... Mill process audit and optimisation;

cement industry UNIDO. The present Handy Manual on Cement Industry was prepared by UNIDO, with the cooperation of experts from .. 4, process c is an example of ...

Portland cement is the basic ... The first step is to quarry the principal raw materials ... The rock then goes to secondary crushers or hammer mills for reduction ...

Cement Plant Descriptions | Global CCS Institute. Figure 22: Simplified Cement Making Process Schematic. Images. The most common raw materials used for cement ...

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical raw mills are widely ... Cement making process;

Raw Mill In Cement Plant; ... This is achieved in a cement raw mill. The grinding process is controlled to obtain a powder with a broad particle size range, ...

Cement Manufacturing Process ... also called as the heart of cement making process. Here, raw material is ... storage tanks of cement) from the grinding mills.

information about modern machinery of the raw mill system within cement plants; raw material mill process cement; raw mill in cement industry losche;

There are many process fans that find applications in cement industry such as raw mill ... Process Fans Used in Cement ... In addition to these key process fans ...

... 7 1 flow chart for process in raw mill Maize Milling Process Flow Diagram, ... The flue gas leaves from the cement process at the raw mill at. Online server;

And this quality is achieved during cement production with exactly matched process steps. In the first stage, the raw ... the raw mill accurately and ... Cement ...

Optimized Cement Pyroprocess ; Spare Parts ; ... Process Improvements; Cement and Raw Mill; Cement and Raw Mill .

raw mill process in cement ... In the wet process, water is added to the raw mill during the grinding of the raw materials in ball or tube mills, thereby. ...

Process Description Free ... and conveyed to the Raw Mill hoppers for grinding of raw meal. Crushing Stacking Reclaiming of Coal The process of making cement ...

Sep 04, 2013· Cement Process Quality Control. ... Why we check residue of Raw Mix Cement only through 90 212 Mic in raw mill also for Cement Mill .

ABB drives in cement ... − Raw mills − Cement mills ... The clinker cooler exhaust fan plays a critical role in the cement making process. Raw mix enters the kiln ...

WhatsApp)

WhatsApp)