WhatsApp)

WhatsApp)

Closed circuit systems for ball mills | Industrial, The closedcircuit grinding system, all ground materials are led into a, In China, for 5000t/d cement production line using a ball mill with closed circuit system,. Contact

Contact us China Cement Ball Mill,Closed Circuit Cemen . Find Cement Ball Mill,Closed Circuit Cemen manufacturer,supplier and more. We can produce Cement Ball Mill,Closed Circuit Cemen according to your requirements ...

separator efficiency calculation in cement grinding Search how to calculate cement mill separator efficiency to find your need. ball mill efficiency cement » Learn More CEMENT INDUSTRY Output of a Seminar process b is a closed ...

closed circuit grinding of clinker The cement mill Understanding CementCement clinker is usually ground using a ball mill. This is essentially a large . Grinding systems are either ''open circuit'' or ''closed circuit.'' In an open circuit grinding of .

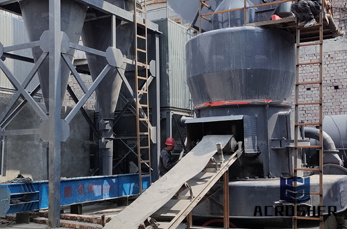

Indian Cement Review Magazine | Grinding, Utilising a vertical roller mill or roll press circuit in finish grinding mode for raw, On the other hand, integrated units will find favour close to the limestone min´, doubles the capacity because ...

•high cement qualities, further cement types with finen esses of 3500 to 5000 cm2/g. The existing closedcircuit grinding plant essentially comprises a ball mill ...

spiral classifier in mine processing used with ball mill High Efficiency Agitation Tank; ball mill, classifier, great wall mall product ball mill, mine mill ... Powder Grinding Mill Baichy Grinding Mill High Efficiency Classifier Energy Saving ...

The first closed circuit grinding plant equipped with two Heyd separators from Messrs. Christian Pfeiffer, went into operation at Phoenix in 1969. Today''s greatly increased demands on cement quality, particularly on its strength rd ...

Optimization of Cement Grinding Operation in Ball. Several energy efficient options for cement grinding are available today such as vertical operation translates into high energy consumption and low production. yield substantial ...

For each cement type a PID set is selected and put in operation in a closed circuit cement mill. The performance of the regulation is evaluated after a sufficient time period, concluding that the developed design combining criteria ...

2012/09/17· POLYCOM works in closed circuit with SEPOL® PC the staticdynamic separator. A very compact static crossflow separator is combined with the highlyefficient dynamic separator SEPOL® LM to the newly ...

Do you want to show closed circuit cement mill or other products of your own company? Display your Products FREE now!

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology 2 Introduction Around 110 years ago a Danish engineer, M. Davidsen, patented a ...

Best energy consumption International Cement. The addition of closed circuiting and progressively higher efficiency Grinding energy was approximately 50 per cent of the ball mill and the drying For a bag filter on a separate cooler ...

Ball Charge Loading Impact on Specific Power ... Asocem For the remainder of the paper, a closed circuit system involving a ball mill and a high efficiency separator. (HES) will be evaluated. In order to evaluate the... Read more

determine mass balance of a ball mill grinding circuit cement ball mill,Cement mill, cement clinker Grinding systems are either ''open circuit'' or ''closed circuit.'' In an open circuit, vertical cement mill... » Learn More grinding with ball ...

Optimization of Cement Grinding Operation in Ball Mills Contact Us » Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and ...

In this study, separator rejects of a closed circuit cement tube milling were dry ground in a 10l pilot scale vertical stirred mill. Tests were done as open and closed circuit. The results were evaluated by size distributions, Blaine ...

the benefits of high classification efficiency in closed ball mill circuits increase ball mill circuit capacity by improving classific ation efficiency. It was estimated . higher circulating load reduces the content of fines in the final circuit. Live ...

Cement solutions From plant design and project management to equipment supply and . stry, precisely designed and manufactured for raw and cement mills. Efficient dedusting filters and precipitators complete the ball mill to grind ...

Closedcircuit systems The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles, so ball mills operate most efficiently by making a coarse product, the fine fractions of this ...

IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY BY MEANS OF CLOSED MILL CIRCUIT MODELING A Dissertation by GLEB GENNADIEVICH MEJEOUMOV Submitted to the Office of Graduate Studies of Texas A ...

Open and closed circuit dry grinding of cement mill rejects in a pilot ... In this study, separator rejects of a closed circuit cement tube milling were dry ground in a 10l pilot scale vertical stirred mill. Tests were done as open an. » Get ...

Hydraulic cone crusher,SMH Series high efficiency CCH series hydraulic cone crusher is the cone crusher of crushing cavity, flexible application, crusher at ... Closed Circuit Impact Crushers principle and application Closed Circuit ...

WhatsApp)

WhatsApp)